VLSI Verification is the backbone of ensuring chip accuracy and reliability before fabrication. In modern semiconductor design, VLSI Verification confirms that the integrated circuits (ICs) and electronic circuits behave exactly as intended. It’s the shield that protects companies from costly design errors, making it a vital part of the vlsi industry

VLSI Verification is a process that ensures every transistor, gate, and signal within a VLSI design functions as expected. It’s part of the design verification in VLSI process, validating that the design meets specifications without flaws.

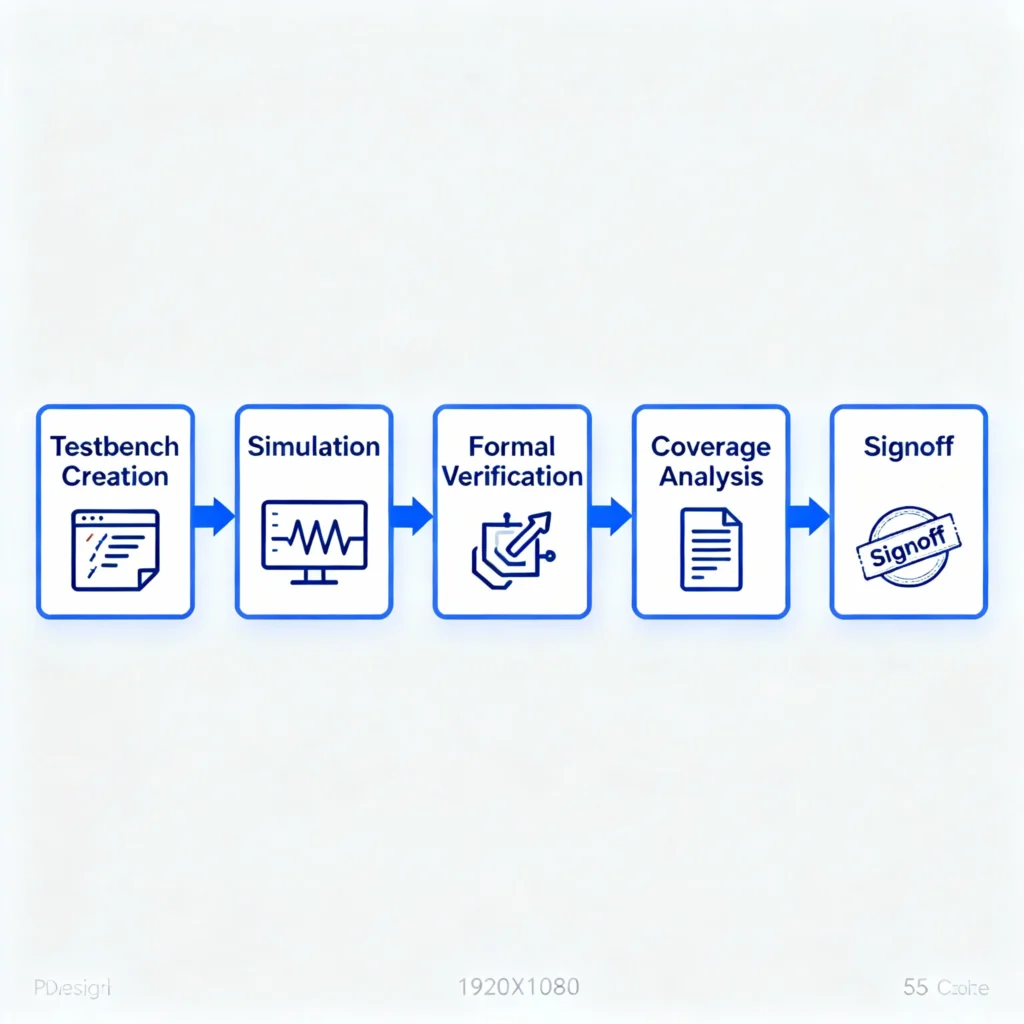

Verification involves simulation, emulation, formal methods, coverage analysis, and more. A strong vlsi verification engineer focuses on preventing design bugs early in the process—before silicon production begins.

Verification is not just about testing; it’s about ensuring quality, reliability, and performance optimization across every step of the design flow.

In the era of large scale integration, even a small design error can result in huge production losses.

Here’s why VLSI Verification is so important:

Without design verification in VLSI, the entire semiconductor process becomes unreliable and expensive.

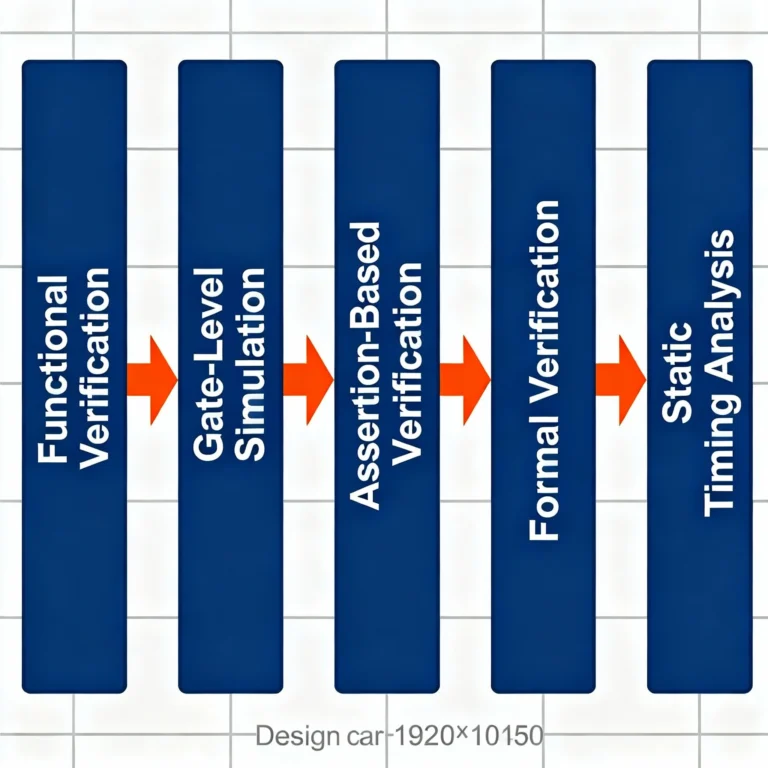

The VLSI design flow defines the roadmap from concept to silicon. Verification plays a crucial role in almost every stage.

Design Flow Overview:

Each phase involves functional, timing, or formal verification steps. The stronger the verification, the higher the design confidence.

Functional Verification ensures that RTL (Register Transfer Level) code works as expected under all possible conditions. It’s the most time-consuming yet vital part of VLSI Verification.

This stage validates electronic circuits and logic functions before synthesis. A vlsiverification engineer must ensure maximum functional coverage.

Once RTL is synthesized to gate level, timing and power constraints must be verified.

These ensure that the synthesized circuit design remains functionally equivalent to the original RTL and meets timing closure.

To execute complex verification tasks, engineers use industry-standard tools and frameworks:

These tools empower verification engineers to perform faster and more reliable design verification in VLSI environments.

A VLSI Verification Engineer is the cornerstone of the chip validation team. Also known as design verification enginee or verification engineer, their role involves ensuring design integrity and coverage completeness.

The job demands hands-on experience, scripting knowledge, and an in-depth understanding of integrated circuits (ICs) and vlsi designs.

Verification is complex due to the immense design size and data volume. Common challenges include

To overcome these, companies rely on modular design flows, reusable based verification IPs, and automated regression setups.

A verification engineer must gain hands-on experience with both hardware and tools.

Continuous learning and experimenting with new verification techniques improve the design process and final chip reliability.

The VLSI industry is booming, and vlsi verification engineers are in high demand. Every semiconductor company, from startups to tech giants, needs verification experts to ensure chip success.

With expertise in asic verification, gate level design, and vlsi technology, engineers can easily move toward leadership roles or specialize in functional verification and system-level validation

VLSI Verification ensures every integrated circuit meets design intent. Through design verification in VLSI, asic verification, and robust functional verification, engineers achieve reliable, high-performance chips.

Whether you’re a vlsi verification engineer, student, or enthusiast, mastering vlsi design verification opens a gateway to exciting opportunities in the vlsi technology world.